SOYA MILK PLANT

Soy milk is a high protein, an iron-rich milky liquid produced from pressing ground, cooked soybeans. Creamy white soy milk resembles cow’s milk but in fact, differs from its dairy counterpart in a number of ways. Not only is it higher in protein and iron content, but it is cholesterol-free low fat and low sodium. It is, however, lower in calcium and must be fortified with calcium when given to growing children.

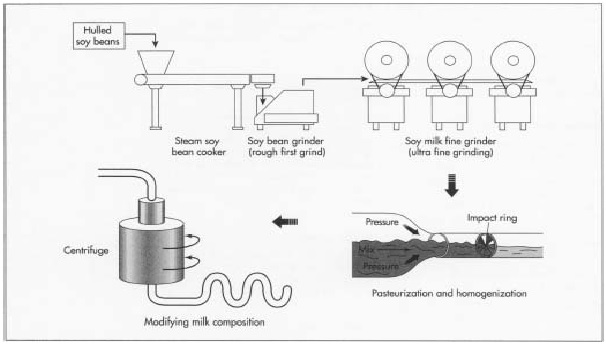

THE MANUFACTURING PROCESS OF SOYA MILK MAKING MACHINE:

The soybean is a low acid food and as such, is a good host for the breeding of harmful bacteria. Thus, the manufacturing process is “aseptic,” meaning that at a certain point in its production, the soy milk is sealed off from any air because it might introduce dangerous bacteria into the product. The development of successful, affordable aseptic production of soy milk has been of tremendous importance in the mass production of this beverage. The initial phases of the production of soy milk do not have to be sealed off to air; only later does this happen.

The traditional soymilk production method involves soaking the beans to rehydrate them, rinsing, resuspension in water and grinding of the beans, followed by filtration to separate the soymilk and fibrous residue. The Japanese developed a slight variation in the traditional Chinese method that improved soymilk yield and improved filtration characteristics but at the cost of a tendency to burn the slurry and the need to use mechanical means to filter the hot mixture, as well as increased energy costs. Usually the ratio of water to beans is in the range from 8:1 to 10:1. About 70% of bean solids, 80% of bean protein, and 89% of the oil end up in the soymilk. The residue left is known by a variety of names: okara, draff, tofukasu, soy pulp, tofu residue, tofu cake, dou zha (Chinese), bejee (Korean), and tempeh gembus (Indonesian).

THE MANUFACTURING PROCESS OF SOYA MILK MAKING MACHINE:

- Procuring the raw materials.

- De-hulling.

- Invalidating the indigestible enzyme.

- Grinding.

- Extracting.

- Blending.

- Aseptic sterilizing.

- Homogenizing.

- Cooling.

- Storing.

- Packaging.