Mayonnaise Manufacturing Preparation Plant

Mayonnaise, informally mayo, is a thick cold sauce or dressing commonly used in sandwiches, hamburgers, composed salads, and on French fries. It also forms the base for many other sauces, such as tartar sauce, fry sauce and many others. It is widely used in all over the world to add some flavor in meal.

Manufacturer of Mayonnaise Processing Plant and Machine

In mayonnaise production, egg yolk is used as an emulsifier which is combined with vinegar, mustard, herbs and spices. Then, oil is added drop by drop as the mixture is rapidly whisked. At last, food preservatives are added so that it can stay fresh for months.

The Process takes the following steps for Mayonnaise Manufacturing Processing Plant:

- At first, an egg is taken which may be used in either powdered or liquid form which is then dispersed into water.

- Then, the other ingredients like vinegar, mustard and other spices are added and mixed until they are fully hydrated and dispersed.

- Then, oil is added as swiftly as possible because the continuous phase will take it up.

- And thus, it results in a dramatic rise in product viscosity as the emulsion is formed and the mayo paste is ready.

The Problems of Mayonnaise Processing Plant

- The mixing equipment which we will use in the mayo production should be capable of dispersing and hydrating the ingredients in a relatively low volume as these the one which adds up the good taste.

- The emulsifying agents and the egg should be properly dispersed and hydrated otherwise the emulsion process can break before adding oil.

- In the mixing process, lumps can easily be formed which cannot be broken down by agitators alone.

- As oil is added continuously, there is a risk of breakdown of emulsion process and thus it is difficult to control the addition of oil manually.

- Specialized equipment should be used to reduce the size of oil droplets to the smallest for maximising the surface area of oil to ensure stable emulsion.

- Aeration must be minimized to maximize product life-span.

The Solution of Mayonnaise Manufacturing Machine

Hindu Engineers works on the problems which you were facing in manufacturing mayonnaise. We have made each solution custom and designed as per the steps and automation described by the end user.

As you all know, flexibility is very important in all aspects of our life. Thus, by keeping this thought in our mind, we have made all our products in that way which are able to handle different ingredients, textures, capacities as well as frequent product changes without any of the delays.

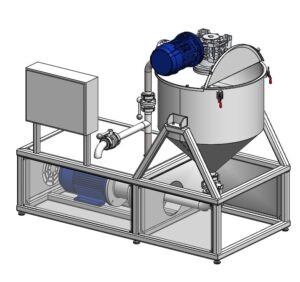

The unit is capable of carrying out the entire process, including rapid preparation of premixes, hydration of thickening and stabilizing agents and preparation of the final oil-in-water emulsion.

And thus for this operation, Inline high-shear mixer by Hindu Engineers is used.

Inline High Shear Mixers consists of a specific arrangement of stator and rotor radials mounted with minimum tolerance for good performance, uniform fineness, and better efficiency.

- Firstly, water is re-circulated from the vessel through the system by the specially designed In-Line mixer by Hindu Engineers. Then, egg is added to the vessel and is quickly wetted out and dispersed into the high velocity liquid stream.

- Then, the ingredients are added in the vessel and the re-circulation continues till they are completely hydrated and dispersed.

- Then, the oil is added in a control manner into Inline high-shear mixer the aqueous phase solution where they are passed to workhead of the In-Line mixer for high shearing process.

- This finely disperses the oil into the aqueous phase, immediately forming an emulsion and then vinegar is added with the last of the oil.

- At last, re-circulation continues to ensure a uniform consistency as the viscosity rises and then process is been completed and the product is discharged.

Advantages:

The World Leader in Blending, Emulsifying & Homogenizing, Disintegration, Particle Size Reduction, Gelling and Solubilizing.

- Extensive test facilitates

- Efficient and Economical solution

- Trial Program

- Worldwide Facilities

- Reduces process times

- Saving cleanup time and cost

- Increasing capacity with higher flow rates

- Lower power requirements

- Worldwide support

- Supervise installation and start-up

- 40+ Years’ Experience

The exceptionally rapid Hindu Homogenizers mixing action substantially reduces process time compared with conventional agitator and mixer and can reduce mixing time by up to 90%.

Our motto is to provide Low Cost and High-Quality Products/Equipment to customers keeping in mind Low Maintenance, Low Power Consumption, High Performance, Durability and Ease of Operation in Shortest Time. – HINDU ENGINEERS.