ALMOND MILK PLANT

A process for preparing almond milk for producing, from a vegetable raw material, a product that can be used as a substitute for animal milk, and in particular cow’s milk, to serve as a basis for creating a line of new products for human consumption, and making it possible to achieve improved nutrition.

ALMOND MILK MAKING MACHINES-HINDU ENGINEERS

Almond milk can be made using whole almonds, or blanched almonds, or almond paste, etc., depending on the customer preference. The challenge is to ensure that all the raw material is used in making almond milk with nothing left as a waste of by-products. The machinery required depends on the input raw material that is to be used, and the type of packaging desired. Multiple packaging options are available: for chilled storage and distribution – bottle or carton or pouch; for ambient storage and distribution–aseptic pouch or carton or bottle, or retorted pouch or bottle or can. The formulations for almond milk are critical in achieving minimum cost per unit volume while giving good product body, mouthfeel, flavor, and shelf stability.

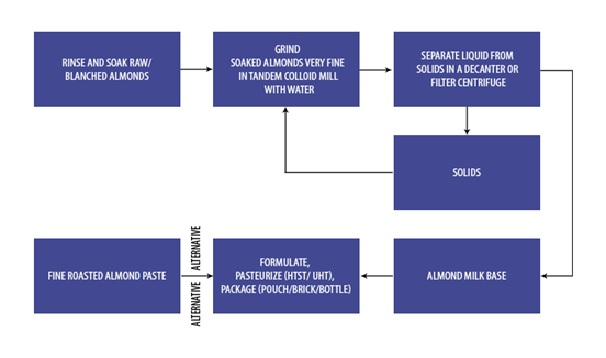

THE PROCESSING COMPRISES OF THE FOLLOWING STEPS FOR ALMOND MILK PLANT:

- Dry grinding non-roasted almond powder.

- Dispersing the ground substance in cold water and adding a stabilizing hydrocolloid in the dispersed ground substance.

- Heating the dispersion at a temperature of approximately 90° C. and bringing it to room temperature until solubilization of the food compounds (proteins, carbohydrates, and minerals).

- Grinding the dispersion in the aqueous phase to reduce the particle size distribution.

- Centrifugally clarifying the dispersion to remove particles that are large enough to be detected by the tongue or the roof of the mouth.

- Sterilizing by “UHT” treatment and cooling the product obtained.

- Homogenizing the product obtained under pressure.

- Aseptic packaging of said product.