HIGH SHEAR HOMOGENIZER FOR SUGAR SYRUP PREPARATION

Dissolving of sugar is a widely used process in the food & beverage industry majorly for beverages like carbonated as well as soft drinks where sugar syrup along with another colorants, stabilizers, preservatives and much more are mixed. Sugar syrups are majorly formed either by using granulated sugar or liquid sugar. The mixing process traditionally involves using of simple agitator along with some heating arrangements for high concentration solution.

PROBLEMS WITH CONVECTIONAL MIXING PROCEDURE FOR SUGAR SYRUP

1. The agitation of the solution is a much more time-consuming process.

2. Higher concentration could be achieved only by heating the solution which additionally adds to the cost and further cooling the solution back to normal is an additional cost and time-consuming.

3. The process is not much stable as the granules leads to crystallization due to heating/cooling.

4. The stability may also be affected due to improper mixing of the solution which further leads to sedimentation and blocking the outlet.

HIGH SHEAR HOMOGENIZERS for sugar syrup preparation process

Hindu Engineer’s range of high shear mixers is a perfect solution to achieve desired homogeneous sugar syrup by perfecting dissolving the granules in the water in much faster processing time than any conventional method. The selection of the homogenizer depends on the desired stability of the solution as well as the throughput required.

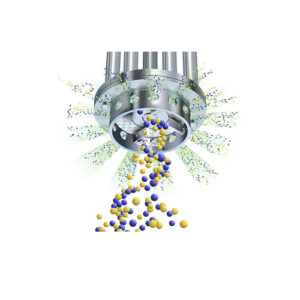

Hindu Engineers work on the principle of shear force being produced as a set of rotor and stator due to the material being flown in between the least tolerance thus causing the material to be sheared. The material is being sucked in from the rotor and thrown outwards to the stator walls due to the high centrifugal force produced due to the rotor and the material is sheared in between the rotor and stator to provide the end results.

1. Intank Batch Type Homogenizer:

>> Suitable for smaller batches up to a maximum of 800 Liters.

>> Portable model to enable usage in multiple vessels.

>> Wide range of stator designs to make it versatile for a wide range of applications.

1. Intank Batch Type Homogenizer:

>> Suitable for smaller batches up to a maximum of 800 Liters.

>> Portable model to enable usage in multiple vessels.

>> Wide range of stator designs to make it versatile for a wide range of applications.

1. Intank Batch Type Homogenizer:

>> Suitable for smaller batches up to a maximum of 800 Liters.

>> Portable model to enable usage in multiple vessels.

>> Wide range of stator designs to make it versatile for a wide range of applications.

2. Inline High Shear Homogenizer:

>> Works best even for higher batch sized up to 10 kL.

>> Wide range of models to choose from: Single Stage, Two Stage & Four Stage Model.

>> Most efficient method for dispersion and results in most superior quality.

ADVANTAGES OF HIGH SHEAR HOMOGENIZERS for Sugar Syrup Preparation

>> Much faster process as the rigorous homogenization leads to particle size reduction and thus increases the mixing efficiency of the granules.

>> Much Higher concentration syrups can be prepared without heating the water.

>> Agglomerate free products thus resulting in the consistency of the solution.

>> Rapid mixing times thus no chances of degradation while processing.