Hindu Engineers a International Company. Our Presence in Middle East: Dubai, Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, The United Arab Emirates, Yemen Europe: United Kingdom: England , Scotland, Germany, Netherlands, Ireland, Italy, France, Spain, Austria, Denmark, Belgium, USSR: Russia, Ukraine, Georgia, Belorussia, Uzbekistan, Armenia, Azerbaijan, Kazakhstan, Kyrgyzstan, Moldova, Turkmenistan, Tajikistan, Latvia, Lithuania, and Estonia Africa : Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, Cape Verde, Central African Republic, Chad, Camoros, Democratic Republic of the Congo, Republic of the Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea-Bissau, Ivory Coast, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe America: USA, Mexico City, Dominican Republic, Colombia, Peru, Chile, Argentina, Montevideo APAC: Malaysia, Thailand, Singapore, Japan, Indonesia, Bangladesh, Philippines, India, Turkey, Laos, Mongolia, Myanmar, Nepal, North Korea, South Korea, Sri Lanka, Taiwan, Vietnam, Yemen, AUSTRALIA & NEW ZEALAND

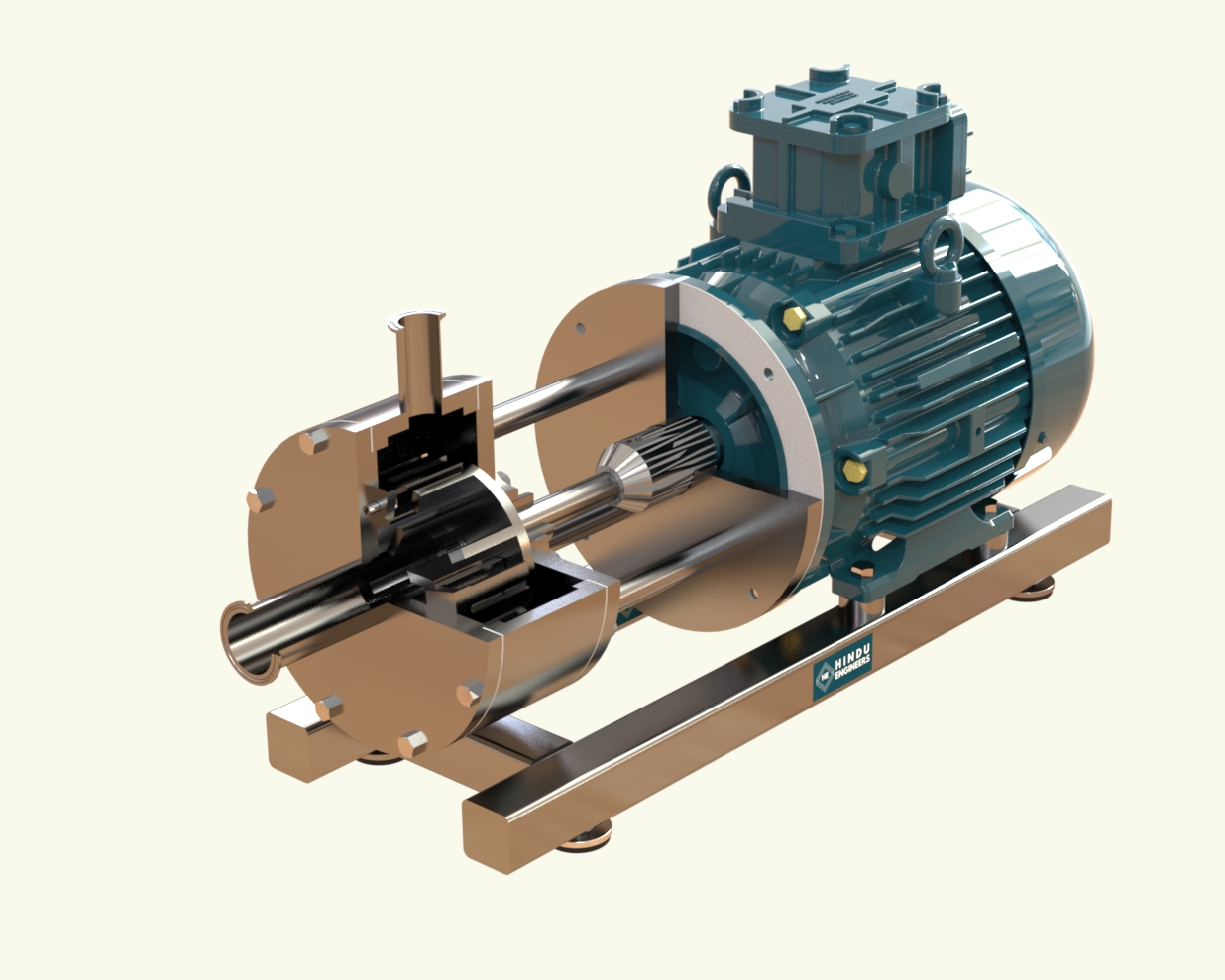

Hindu manufacture high shear homogenizer for works on the principle of the high centrifugal force produced due to the high rpm of the rotor mounted on the main spindle and thus producing a very high shear due to the specially designed minimal tolerance between the rotor and stator. A high shear homogenizer is homogenizing the feed particle into the fine droplet size and the degree of homogenization is very effective and capable for diverse products such that creams, lotion, flavor emulsion, dispersion of fine particles, blending of semi-liquid, dissolving, pasteurization, etc.

Hindu makes High Shear homogenizer which is characterized and acceptable by their flexibility, economically, technically as well as safety aspects. It works in a minimal tolerance between rotor and stator which provides much more fine results.